Sample HubSpot User

Recent Posts

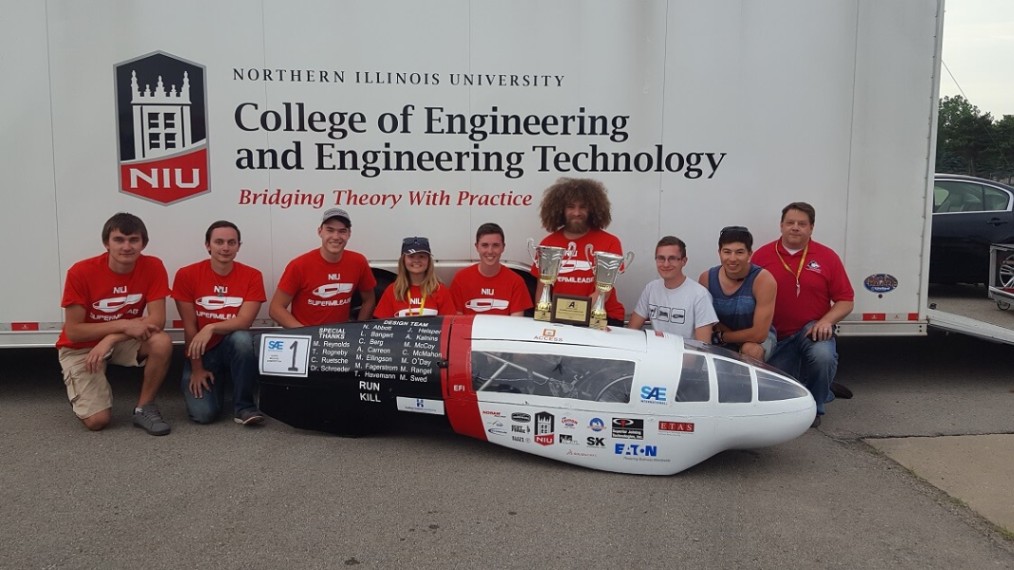

Northern Illinois University - SAE Supermileage Team 2018

NIU placed 2nd Overall at the Annual SAE Competition and achieved a new team record of 1,888 MPG! The NIU team also won the Endurance Award by traveling close to 70 miles without breakdowns, and was the first team to complete the rigorous technical inspection from the Society of Automotive Engineers. Superior Joining Technologies, Inc. is proud to be a sponsor and plans to support the NIU Supermileage team in the future for all of their Welding and Laser cutting needs. CONGRATULATIONS NIU!!

Superior Joining Technologies' President Teresa Beach-Shelow Featured as a Leader

Read the story by Ryan Forsell...

Superior Joining Technologies Attains Updated Quality Certifications

As of March 13, 2018, Superior Joining Technologies, Inc. has been recertified

to the updated ISO 9001:2015 and AS9100:2016 quality standards. We are

delighted to serve our customers to even higher standards through the well-defined

and documented procedures this certification requires. While we’ve

always been committed to quality in our products and services, this certification

ensures a more productive environment through faster identification and

resolution of quality issues, among many other benefits.

We partnered with Smithers Quality Assessments, www.smithersregistrar.com,

an accredited quality and environmental management systems certification body,

to achieve our certification.

Come visit us at Booth #107 at the MRO Americas Conference!

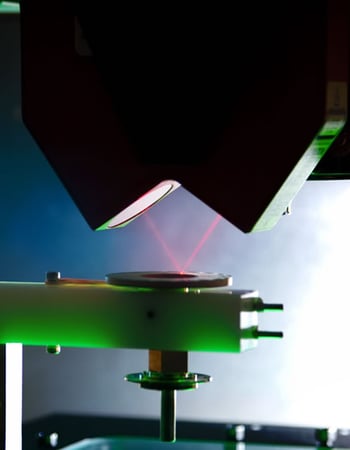

Advanced-Technology Dimensional Measuring System

Superior Joining Technologies, Inc. is excited to announce the recent addition of an Advanced-Technology Dimensional Measuring System to our metrology department. The integration of three different sensors in one system enables us to provide definitive verification of our products.

Video Measurement / Optical Comparator

The Optical sensor provides two complementary methods of measure. Video measurement is primarily used as an Optical Comparator for non-contact measurement applications.

The 10:1 Zoom Optics mode provides the highest-level resolution optical/video performance. It is specifically designed to measure smaller parts, with fine detail geometry with fully automated program capability for rapid throughput of larger part quantities.

Touch Trigger Probe

Touch Trigger Probe

Single-point touch trigger probing adds versatility to our measurement capability. Using a touch trigger probe, we can measure intricate 2- or 3-dimensional features that are difficult to image, or surface boundaries that are inaccessible to video.

DRS™ Laser

The DRS™ (Digital Range Sensor) Laser Probe provides non-contact, high resolution 3-dimensional surface contouring to supplement video measurements.

As one of the sensors in this multisensor measurement system, the metrology software integrates the DRS Laser data points as easily as those gathered by video measurement. Both linear and area scans are easily programmed into automatic measurement routines for accurate measurement of surface contours.

|

Smartscope Specifications |

|

|

XYZ Stage Travel: |

300 x 150 x 200 mm |

|

Area Accuracy: |

(1.8 + 4L/1000) µm |

|

Z Accuracy: |

up to: (1.4 + 6L/1000) µm |