Precision CNC Machining Services

Manufacturing fuels the global economy by creating the items people depend on every day and driving technological advancement. A batch of flawed components can hurt the ability to deliver products to market or develop innovative solutions, however.

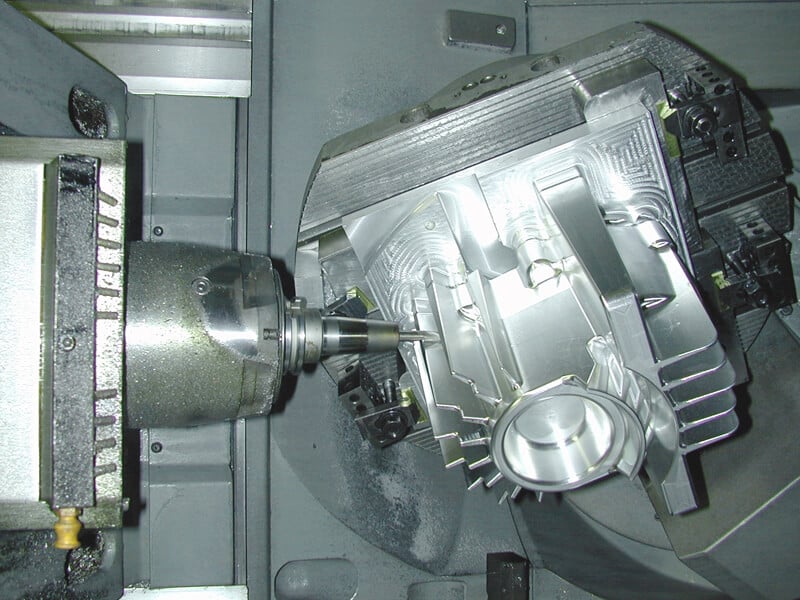

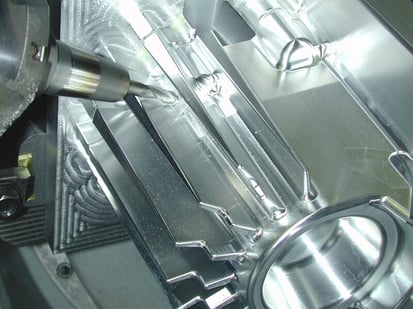

Ensure your production lines receive a steady supply of conforming components with high-value precision CNC machining services from Superior Joining Technologies. We an Illinois-based manufacturing solutions provider that specializes in turnkey 5 axis CNC machining services for critical applications. Superior Joining Technologies, Inc. also serves as a test and demo facility for machine tool manufacturers and cutting tool companies.

What Is CNC Machining?

Short for computer numerical control, CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It’s used to control a range of sophisticated machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks are accomplished with a single set of prompts.

CNC machining has an array of advantages over manually controlled fabrication methods, where operators are needed to prompt and guide machining tools by levers, buttons, and wheels.

- Manufacturing cost savings

- Improved production speed

- Heightened safety

- Increased efficiency

- Reduced downtime

Aerospace Parts Machining

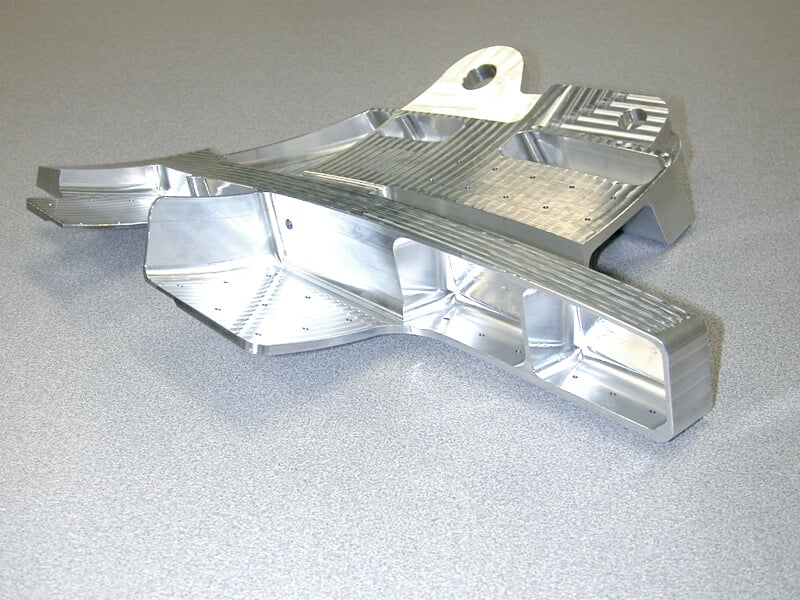

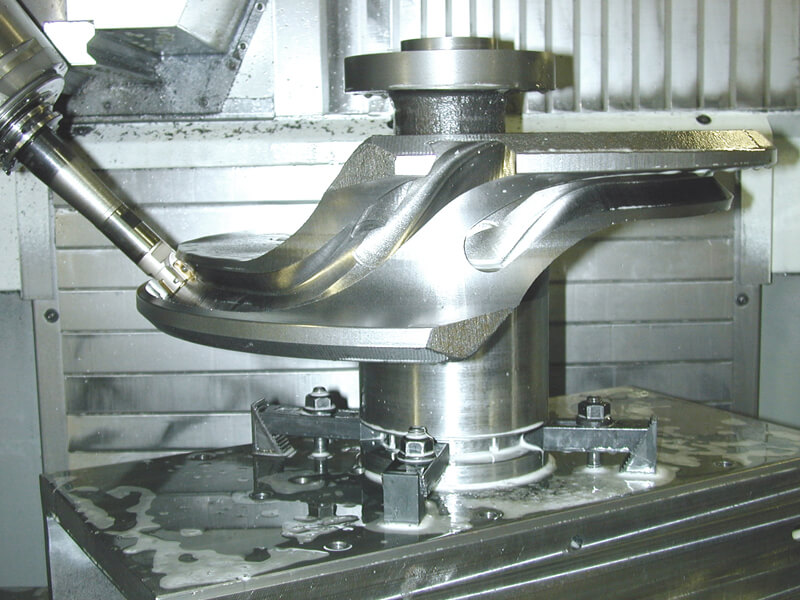

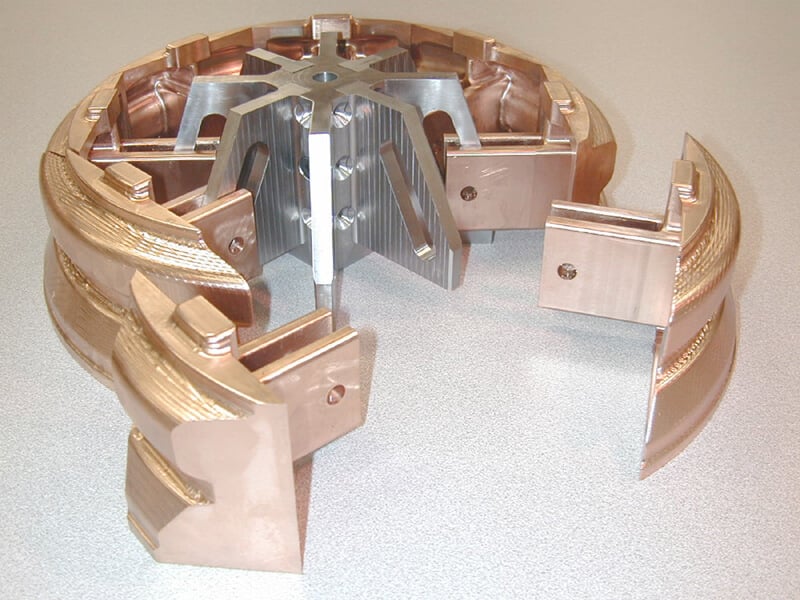

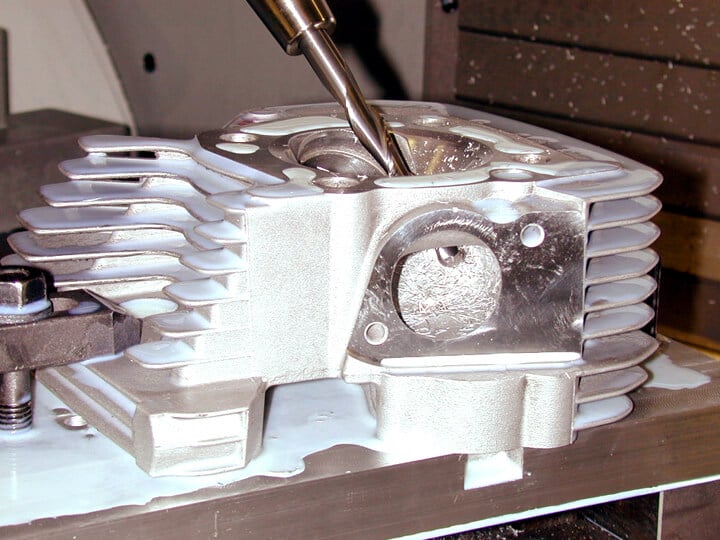

As a 5-Axis CNC machining company, Superior Joining Technologies, Inc. uses all of the advantages to produce high-quality precision machined aerospace parts. Increased speed and superior surface finish are achieved with fewer setups. Complex or ruled surfaces can be machined in one pass, speeding delivery. Compound angle holes and undercuts can be cut quickly and accurately. Using an integrated automated pallet system, we can use unattended machining even on high-precision complex parts. As required, we can utilize our extensive NADCAP supply chain for heat treating, plating, painting, and other required processes and finishes.

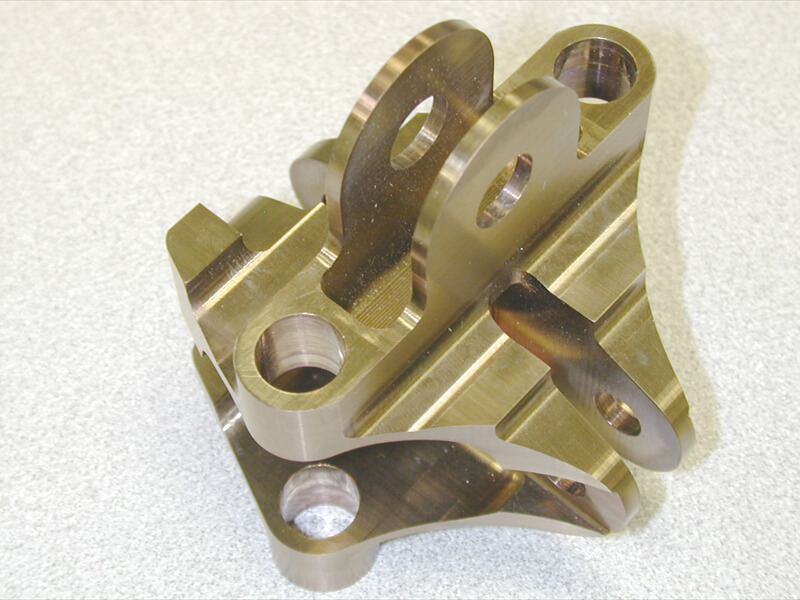

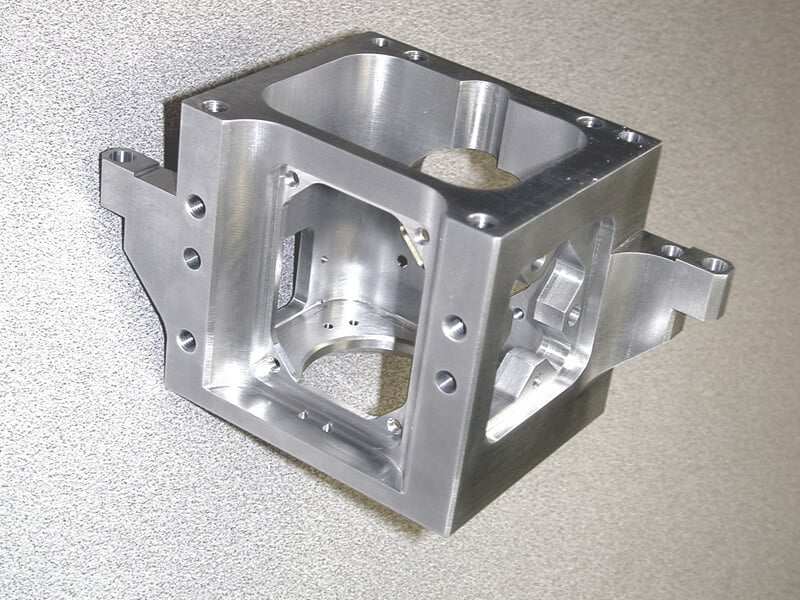

We can create just about any shape or form using CNC machining. Our tools can make thousands of cuts per hour, with every cut from the first to the last having the same micrometer level of precision. Our 5 axis CNC machining services are perfect for aviation, aerospace, medical, nuclear, industrial, maritime, and defense industries. Provide complete traceability and documentation of product manufacturing to AS9100:2016, Rev. D, and ISO9001:2015 standards.

Contact the team at Superior Joining Technologies, Inc. for more information regarding our precision CNC machining services.

5-Axis Machining Specifications

Tolerances

As close as +/- .0002"

Materials

Our precision 5 axis CNC machining services are capable of producing intricate parts from a range of materials. While we can fabricate finished parts from just about anything, here’s what we work with most often.

- Aluminum - All grades

- Tool Steel - All grades including tool steel, Finkl FX, D2, S7

- Hard cutting of Tool steel up to 60 Rockwell

- Stainless steel - All grades including 300 Series, 400 Series, 17-4PH, 15-5PH

- Castings

- Titanium

- Tungsten

- Inconel and other nickel alloys

- Plastics

- Nylons

Machining Equipment List

| Deckel Maho Gildemeister DMU 60 eVo Linear Full 5 Axis CNC Universal Machining Center Linear motor for each axis Capacity: 25.6" X, 19.6" Y, 19.6" Z Spindle Speed: 18,000 rpm Laser tool setter and touch probe |

Mikron UCP 600 Vario with Integrated Automation & 120 Tool Tower Full 5 Axis CNC Vertical Machining Center Capacity: 23.6" X, 17.7" Y, 17.7" Z Spindle Speed: 20,000 rpm Laser tool setter and touch probe |

Deckel Maho Gildemeister DMU 100T Full 5 Axis CNC Universal Machining Center Capacity: 42.5" X, 28" Y, 28" Z Spindle Speed: 18,000 rpm Feed Rate: 591 ipm Laser tool setter and touch probe |

| Deckel Maho Gildemeister DMU 125-P Hi-dyn Full 5 Axis CNC Universal Machining Center Capacity: 49.2" X, 34.5" Y, 34.5" Z Spindle Speed: 18,000 rpm Laser tool setter and touch probe |

Deckel Maho Gildemeister DMC 125-U Hi-dyn Full 5 Axis High-Speed CNC Machining Center Capacity: 49.2" X, 34.5" Y, 34.5" Z Feed Rate: 787 ipm Laser tool setter and touch probe |

Deckel Maho Gildemeister DMU 80-P Hi-dyn Full 5 Axis CNC Universal Machining Center Capacity: 31.5" X, 27.6" Y, 23.6" Z Spindle Speed: 18,000 rpm Feed Rate: 591 ipm Laser tool setter and touch probe |

Better Processes, Superior Parts

SJTI has state-of-the-art machine tools, tooling, and software. With a thorough knowledge of Autodesk’s PowerMILL machining software, we can determine and write the most effective tool paths for a job. We have partnered with DMG Mori, a worldwide cutting tools leader, to maximize our machining capabilities. Together, we have developed an efficient, accurate, and cost-effective process that delivers superior results every time.

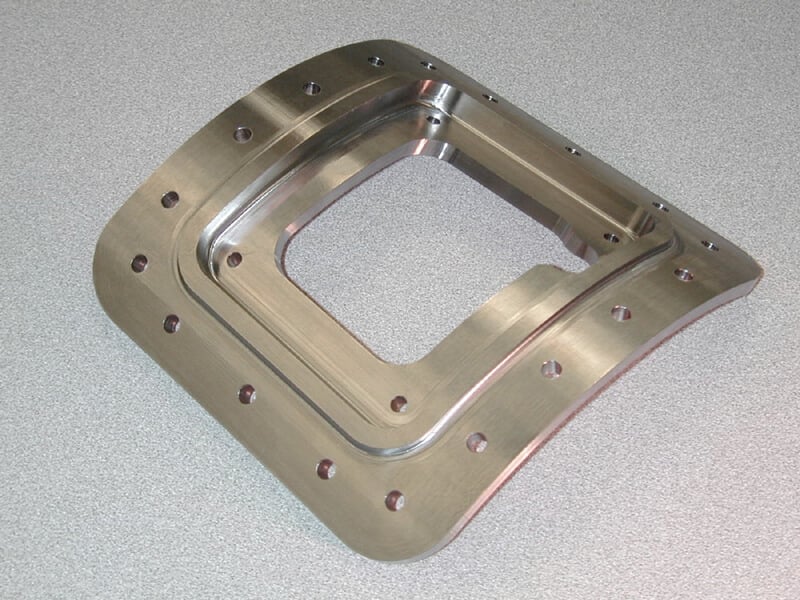

We utilize innovative five-axis machining to produce machined parts for critical applications across a range of industries. With this process, increased speed and superior surface finishes are achieved with fewer setups. Complex or ruled surfaces are machined in one pass, which speeds up delivery. Compound angle holes and undercuts are cut quickly and accurately. Using an integrated automated pallet system, we can implement unattended machining even when manufacturing tight-tolerance, complex parts.

|

Do complex parts in one or two setups

> Machine on 5 sides of a part with one setup

> Saves set up on time

> Reduces error

> Reduces fixturing costs |

Use shorter cutters > Faster feed rates > Higher accuracy > Better finish > Less time hand benching |

Reach geometry that is impossible on 3 axis machines. Allows faster and cheaper completion of: > Prototypes > Short-run production parts > Drilling holes with compound angles |

We Machine, You Focus On Core Processes

Building a high-performing assembly often requires dozens, if not hundreds, of parts that demand a substantial amount of workforce hours to make. Integrating processes like CNC machining into a production line is challenging, which can drive up costs and delay finished product delivery. Enable your staff to focus on their primary functions by partnering with SJTI for CNC machining. Typically, outsourcing this process costs noticeably less than manufacturing in-house. These savings are realized by reducing:

- Labor costs

- Overhead maintenance costs

- Distractions

- Redundancy costs

Working with your engineering staff, we can machine a functional prototype from a variety of materials to meet design specifications. When the prototype has been developed and approved, we leverage the knowledge, fixturing, and machining strategies developed during that process to produce high-quality parts on time and within budget. When required, we utilize our extensive supply chain to accomplish preparatory and secondary processes, such as chemical and mechanical analysis, heat treatment, plating, and painting. We have an in-house inspection team that performs high-value surface non-destructive testing, as well.

Letting SJTI handle additional processes can streamline your supply chain. This saves money, improves part delivery timelines, and frees you to focus on your core business. Optimize your manufacturing process with effective precision CNC machining services from SJTI. Whether you need a prototype, small batches for testing and validation, or large quantities of parts, SJTI is your CNC machining source.