Non-Destructive Testing (NDT) Services

Societies rely upon a range of devices for day-to-day functions, from satellites and aircraft to medical equipment and power stations. Products manufactured from materials with undetected flaws can prematurely fail, however, which may lead to revenue losses, facility closures, and injury or death.

Ensure materials for your application are of the utmost integrity with reliable nondestructive testing (NDT) services from Superior Joining Technologies. We are a Nadcap Accredited NDT Services leading provider of surface flaw detection assessments for a range of industries, but our specialty is proving parts for critical functions are fit for purpose.

NDT is also known by other terms such as Non-Destructive Examination (NDE), Non-Destructive Inspection (NDI), and Non-Destructive Evaluation (NDE).

What is Non-Destructive Testing?

Non-destructive testing (NDT) is a group of analysis techniques used to evaluate the properties of materials, components, or systems without causing damage. Also called nondestructive examination, or NDE, and nondestructive inspection, or NDI, this evaluation method detects imperfections that may negatively impact equipment performance and longevity, as well as user health and safety.

Capable of examining materials without destroying their usefulness, NDT offers a range of benefits. Here are a few examples:

- Less waste

- Reduced downtime

- Accident prevention

- Identify areas of concern before failure

- Comprehensive testing

- Increased reliability

- Improved production efficiency

Our Process

Superior Joining Technologies verifies the reliability and safety of materials, products, and equipment with industry-leading surface inspection services. We have a thorough knowledge of the processes involved and the dedication to turnaround jobs quickly and affordably. Our in-house capabilities include Continuous Wet Bench Fluorescent Method for:

Visual inspection, also called VI or VT- VT is the oldest method of nondestructive testing. It’s the process of looking over a piece of equipment using the naked eye to look for flaws. A visual examination can be used for internal and external surface inspection of a variety of equipment types.

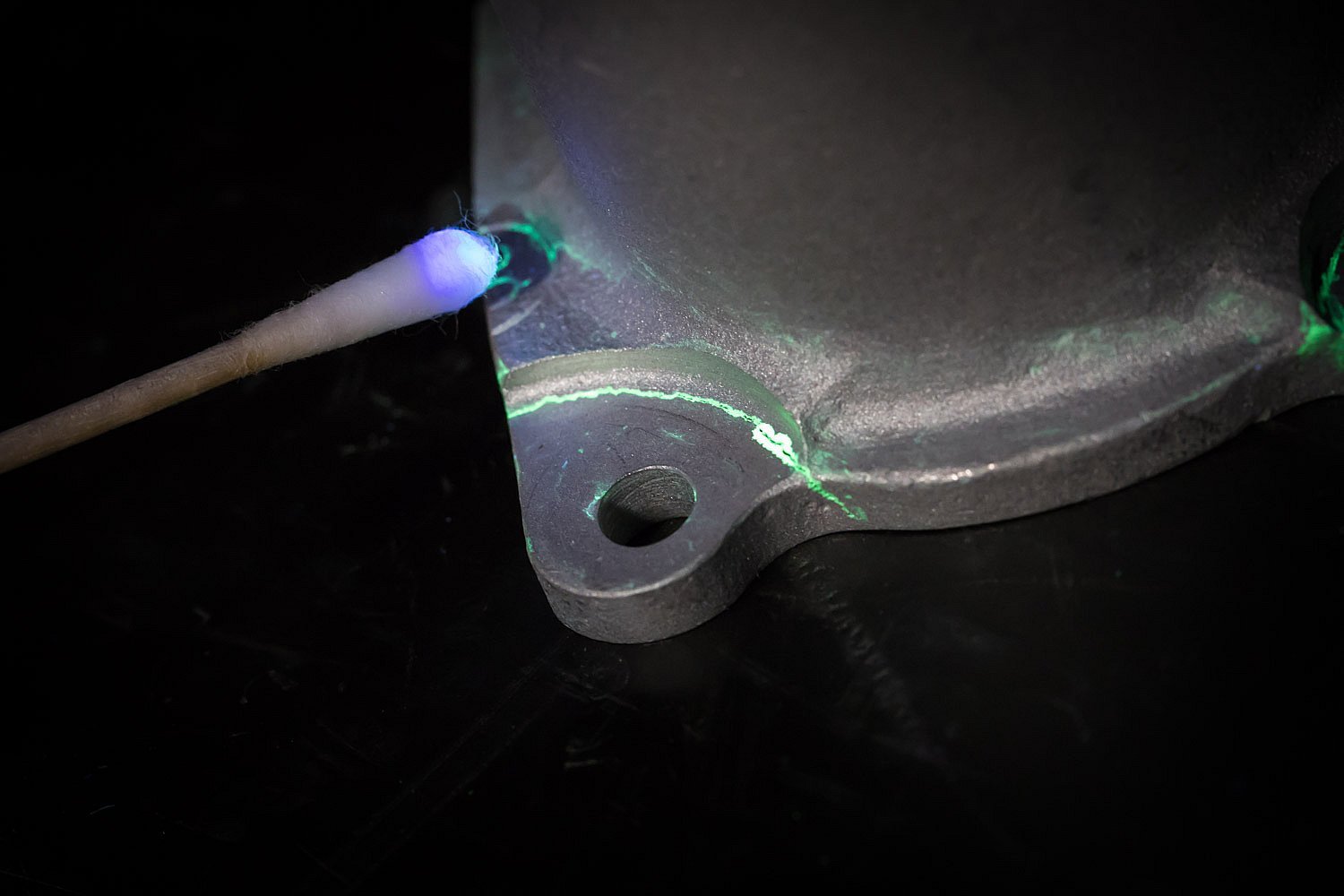

Liquid penetration inspection, or LPI- LPI identifies surface discontinuities in a range of parts, but it’s ideal for use on non-porous materials such as plastics, ceramics, and metals. For this NDT technique, liquid penetrant is pulled into the surface-breaking crack by capillary action. After excess penetrant removal, a developer is applied to draw out penetrant from the crack and produce a surface indication. SJTI LPI process includes sensitivity levels 2,3, & 4.

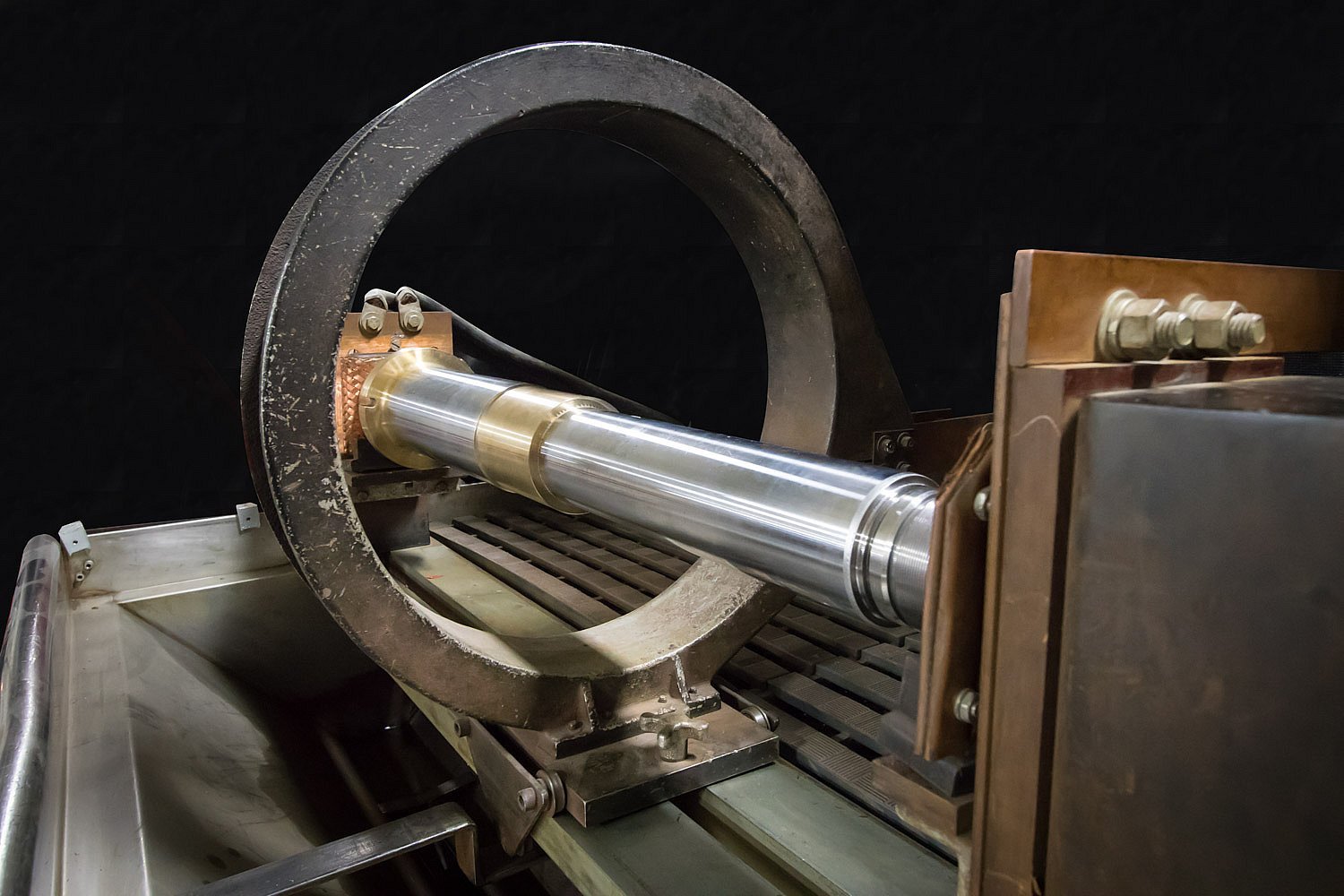

Magnetic Particle Inspection, or MPI - is an NDT process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials, such as iron, nickel, cobalt, and alloys. The process begins by running an electrical current through the component. Any cracks or defects will interrupt the magnetic lines of flux and cause magnetism to spread out, which creates a flux-leakage field at the damage site. Metal particles are then spread over the component. If there are any flaws on or near the surface, the flux leakage field will draw the particles to the damage site and create a visible indication of its approximate size and shape.

Industries Served

Our surface NDT inspection methods are used to assess a range of parts before being released for use. Industries that can benefit from our services include:

- Aviation

- Aerospace

- Space-related projects

- Medical

- Nuclear

- Industrial

- Pipe Lines & Fracking

- Maritime

- Defense

Certifications

SJTI holds an F.F.L. (Federal Firearms License), FAA Repair Station Certificate, along with ISO 9001 & AS9100 certifications. Superior Joining Technologies, Inc. has earned the National Aerospace and Defense Contractors Accreditation Program, or NADCAP, certifications for nondestructive testing since 2008.

The SJTI Difference

SJTI’s highly trained NDT staff includes two technicians who’ve earned Level III certifications in accordance with NAS410 (National Aerospace Standard) for MPI and LPI. SJTI is also approved by specific customers for NDT processes those customer approvals include: The Boeing Company, Woodward, Collins Aerospace, and GE. A third technician is an ASNT-certified Level II in LPI. They inspect materials for a variety of reasons, but common ones include:

- Finding surface and near-surface flaws or irregularities

- Product evaluation

- Identifying areas of wear

- Confirming safety and reliability

Our extensive knowledge of NDT and materials testing means we can select the best technique to detect flaws and irregularities in products and equipment, which avoids damage, operating inefficiencies, and in-service failure before they cause catastrophic consequences and financial losses. Optimize your application with high-quality Nadcap accredited NDT inspection services from the SJTI. We have you covered. Give us a call for more information about our non-destructive testing services.