Magnetic Particle Inspection (MPI) Services

Magnetic testing (MT), or magnetic particle inspection/wet-bench method, is a non-destructive method for detecting defects in ferrous metals. A magnetic field created with an AC or DC current is applied through the material, revealing flux leakage at a surface or near-surface flaw.

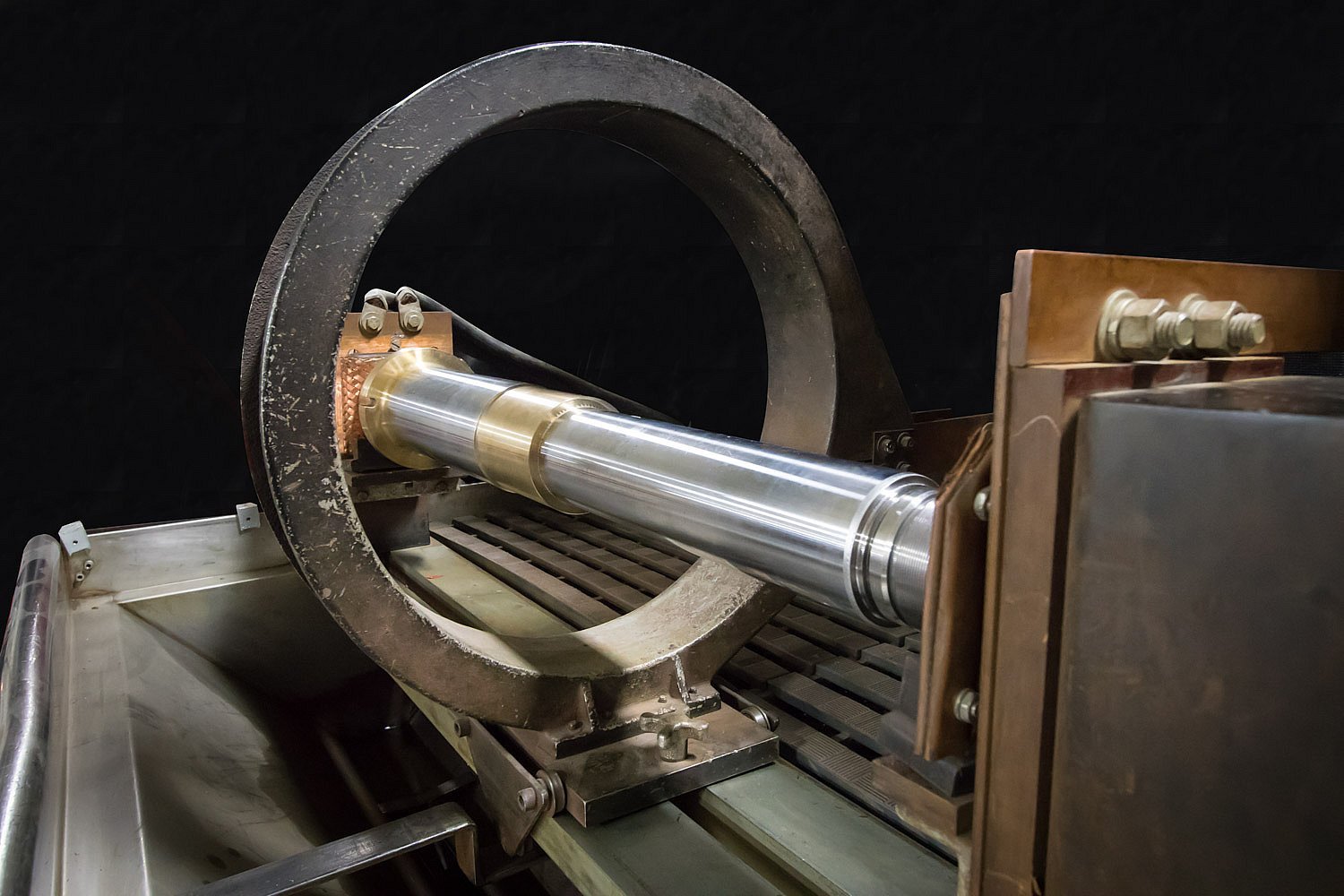

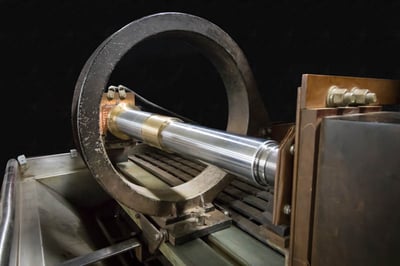

Our magnetic particle inspection (MPI) services involve fine magnetic iron oxide particles coated with a fluorescent dye and held in a suspension liquid, which are attracted to the magnetic (flux) field in the area of a defect to reveal it as a build-up of particles. The photograph to the left shows an airplane crankshaft being viewed with ultraviolet light (blacklight) as part of the magnetic testing process. The zoomed-view shows the presence of fatigue cracks on the plate around the crankshaft.

What Is Magnetic Particle Inspection Used For?

What Is Magnetic Particle Inspection Used For?

Magnetic Testing (MT), or Magnetic Particle Inspection, is a non-destructive method used to detect defects in ferrous metals. A magnetic field created with AC or DC current is applied through the material, revealing flux leakage at the surface or near-surface flaws.

Benefits and Applications of MPI

Magnetic testing is used on ferromagnetic metals such as iron, nickel, and steel. While it is used across a number of industries, the aerospace industry is the most common. MT or MPI is often used to inspect forgings, castings, and welds of ferrous metals used for generator components and engine parts. Valves, pumps, bolts, fans, rails, and blades are all examples of parts that commonly undergo magnetic testing. In addition to aerospace, industries such as power generation, oil and gas production, and off-shore operations utilize MPI to ensure the integrity and safety of the material or various parts.

Our magnetic particle testing services are not only beneficial but necessary in guaranteeing the dependability and shape of parts and equipment. Exposing any defects, cracks, or abnormalities in a piece allows companies to plan the repair ahead of time — before the costs of repair or replacement skyrocket. This aids in safety as well, providing crucial information on a part before any accidents occur due to a small flaw. MPI is a cost-effective, reliable inspection for ferromagnetic metals in a variety of industries.

Magnetic Testing vs. Penetrant Testing

Magnetic particle inspection induces a magnetic field using either an AC or DC current, exposing cracks or impurities through a flux leakage, while penetrant testing is the application of a penetrating dye that settles into any seams or openings to expose flaws. MPI can be used only on ferrous metals, while PT can be used on nearly any nonporous material. Penetrant testing involves a chemical dye that might not be suitable for every material, while MT has a limited range of materials as well. The expert team at Superior Joining Technologies can help determine the proper inspection for your needs and application.

The Superior Joining Difference

As a Nadcap magnetic testing company, our magnetic particle inspection (MPI) services involve fine magnetic iron oxide particles, coated with a fluorescent dye and held in a suspension liquid, are attracted to the magnetic (flux) field in the area of the defect and to reveal it as a build-up of particles. The photograph at left shows an airplane crank-shaft being viewed with ultraviolet light (backlight) as part of the magnetic testing process. The zoomed-view shows the presence of fatigue cracks on the plate around the crankshaft.

SJTI has the capability to test parts up to:

- 15 inches in diameter

- 90 inches in length

- 1 ton in weight

Download PDF Info sheet on Magnetic Particle Inspection.

Superior Joining Technologies has conformed to ASTM-E 1417 Standard Practice for Liquid Penetrant Inspection since May of 2007 and was Nadcap Accredited in July 2008. Their processes have been approved by GE, Boeing, Unison, Collins Aerospace, Safran, and Woodward. As a trusted Nadcap magnetic testing company, our team of professionals is always ready to help, offering excellent service in addition to reliable services. Get in touch today to discuss our magnetic particle inspection (MPI) services or to answer any questions you may have.