Penetrant Testing Services

What is LPI Testing?

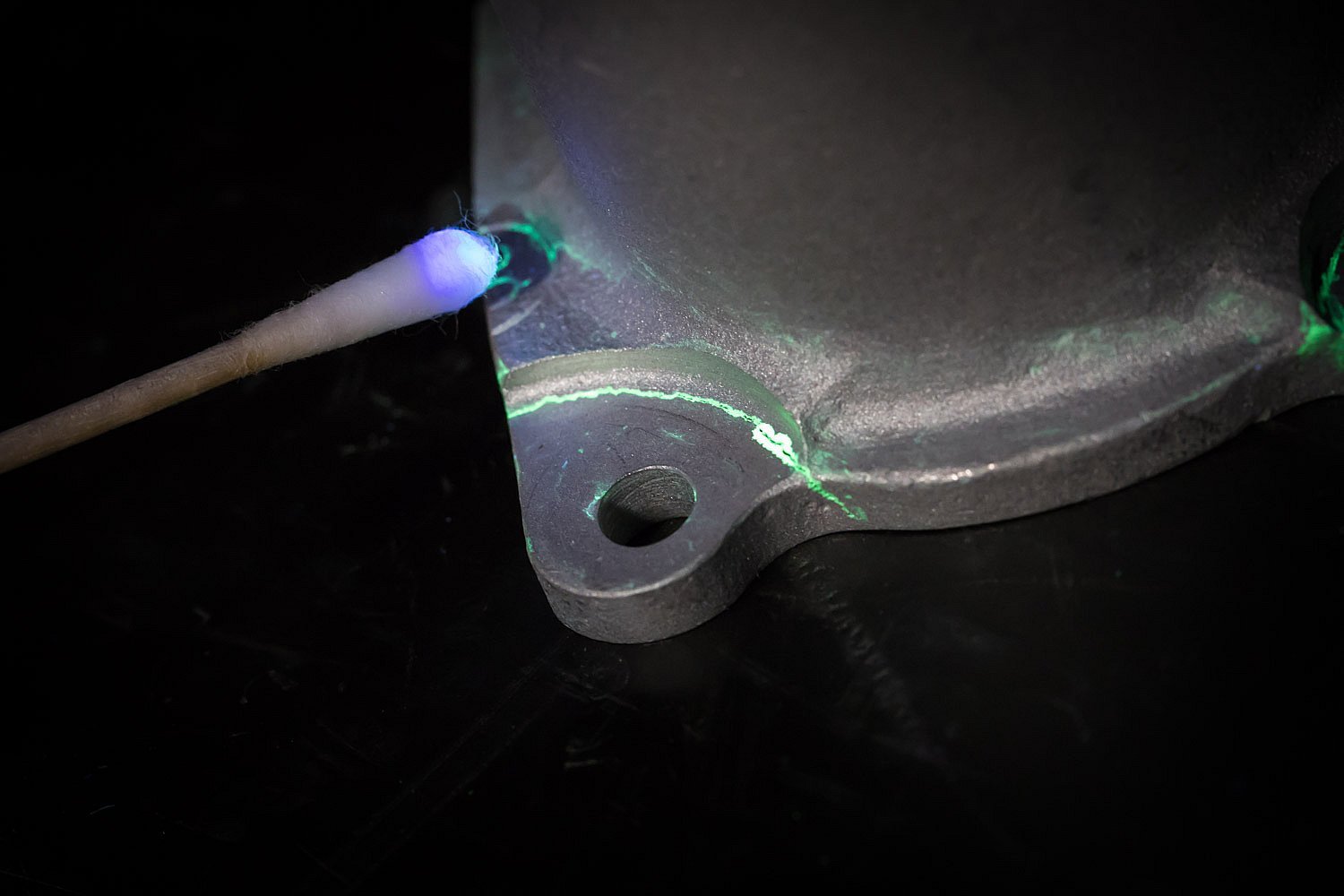

Liquid penetrant inspection (LPI), also called penetrant testing (PT), or fluorescent penetrant dye inspection, is a widely accepted inspection method used to detect surface cracks and defects in metals, ceramics, and plastics. The liquid penetrant may be applied to the component through dipping, spraying, or brushing and will detect casting and forging defects, cracks, micro shrinkage (or porosity) and leaks in new products, and fatigue cracks on in-service components.

Our Nadcap liquid penetrant inspections are performed quickly and easily on a variety of nonporous materials. The process involves applying a visible dye penetrant to the piece being inspected, allowing it to sit and make its way into any cracks or seams and thus visibly exposing any flaws.

Penetrant Testing Applications

Penetrant testing is a commonly used form of inspection used throughout a wide range of industries due to both its reliability and simple, affordable process. PT or LPI can be used to detect abnormalities or flaws in forgings, castings, and welds that are often invisible to the naked eye, whether it be a small seam, a fatigue crack, or a weld impurity.

Liquid penetrant inspection is a tried and true process in industries such as oil and gas, power generation, and aerospace. Critical components like engine parts, turbines, pressure bodies, and blades commonly undergo a form of penetrant testing. This helps manufacturing companies locate any defects that may be missed by other inspections, while the automotive and pharmaceutical industries can ensure safety through LPI.

Levels of Penetrant available: 1/2, 1, 2, 3, and 4.

- Level ½ – Very low sensitivity

- Level 1 – Low sensitivity

- Level 2 – Medium sensitivity

- Level 3 – High sensitivity

- Level 4 – Ultrahigh sensitivity

SJTI generally uses the highest 3 Levels of Penetrant Sensitivity: Levels 2, 3, and 4 for evaluating parts.

Penetrant Testing Benefits

The benefits of penetrant testing are far from minimal, providing crucial information across a variety of applications. By pinpointing defects, cracks, or abnormalities within a piece, companies can immediately plan the repair before it causes real damage. Penetrant testing saves companies money by being the most cost-effective inspection and allowing them to repair equipment before excess costs accumulate. This form of testing can also be performed in-shop on any shape of equipment, no matter how complex. Liquid penetrant testing is a convenient, highly reliable, and cost-effective process that ensures the dependability of parts and equipment across industries.

Penetrant Testing vs. Magnetic Particle Testing

Penetrant testing is an inspection that uses chemicals/dyes, allowing the liquid to seep into any cracks or tears. Magnetic particle testing, on the other hand, utilizes a magnetic field to pinpoint a flaw through a visible break in the field. PT can be used on most nonporous materials, while MT can only be used on ferromagnetic metals, such as iron and nickel. Our professionals are experienced in providing both Nadcap liquid penetration inspection and magnetic particle testing and will use the proper process and materials accordingly.

The Superior Joining Difference

Since May 2007, Superior Joining Technologies has conformed to ASTM-E 1417 Standard Practice for Liquid Penetrant Inspection and was Nadcap Accredited in July 2008. Their processes have been approved by Boeing, GE, Unison, Safran, Woodward, and Collins Aerospace. Experts on the team provide exceptional customer service in addition to reliable services and are always ready to help. For more information on our penetrant testing services, contact us today.