Direct Metal Laser Melting (DMLM)

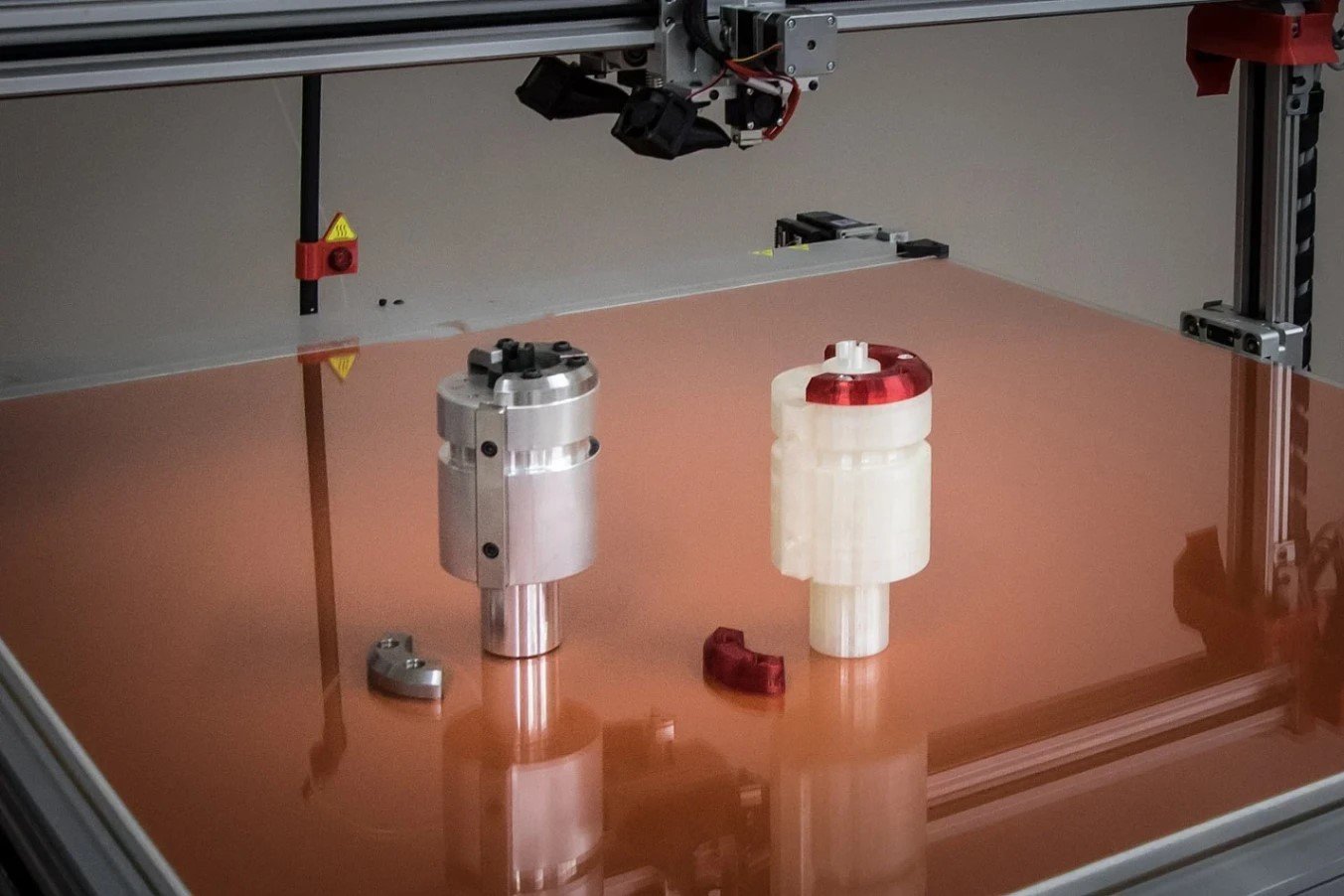

Direct metal laser melting (DMLM) or selective laser melting is very similar to more traditional direct metal laser sintering (DMLS) processes, except the material used is completely melted to create incredibly thin liquid pools that solidify as they cool.

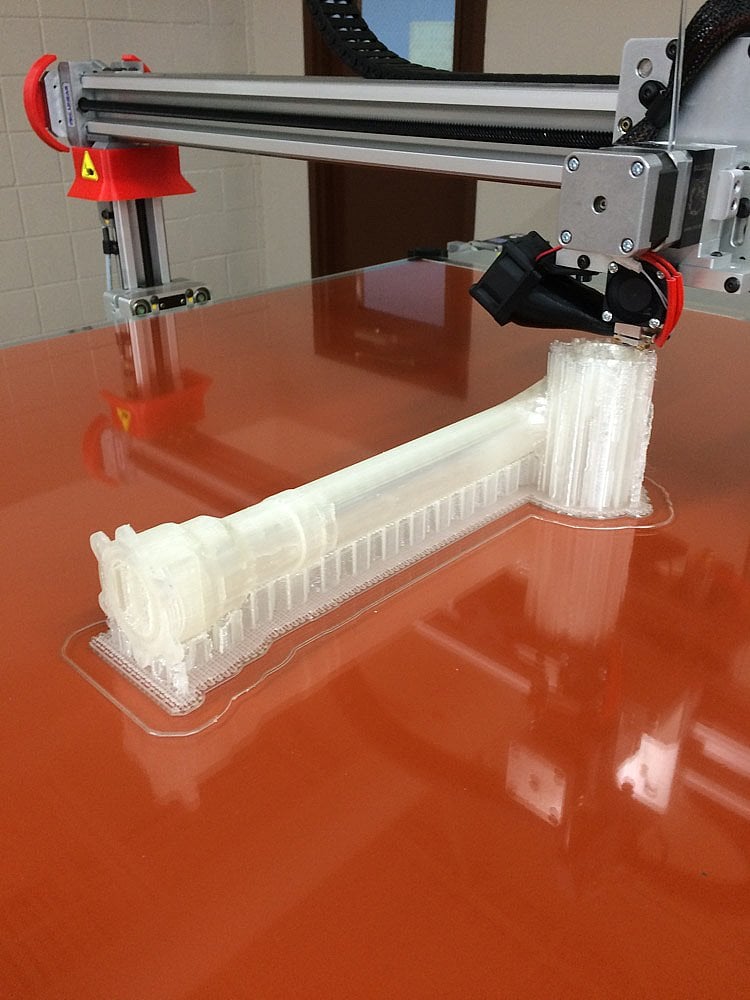

Our DMLM machine provides a layer thickness down to 15 - 30 μm and a production speed of 1 - 5 cm3/h (depending on material) with a 100 W fiber laser. This gives us the ability to develop and produce incredibly detailed and elaborate structures in metal materials, including components that the traditional milling and machining process don’t allow.

In addition to selective laser melting services, we also offer fused filament fabrication and laser powder deposition. Contact us to receive more information about our 3D metal printing services.