5-Axis Laser Cutting

What Is 5-Axis Laser Cutting?

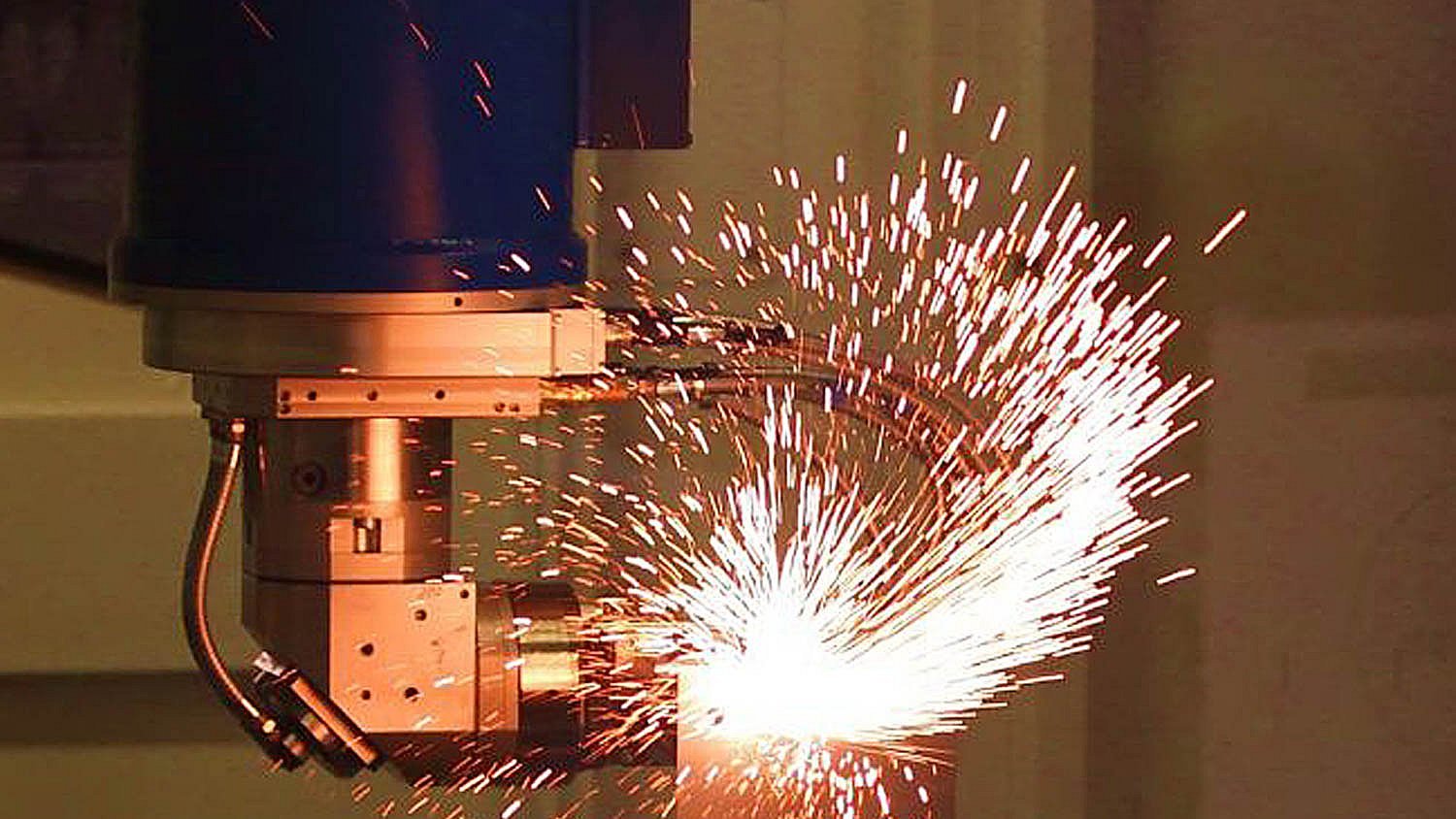

5-axis laser cutting is laser cutting that enables the tilt and rotation of the table, allowing the work on three-dimensional parts that requires drilling and cutting on difficultly curved surfaces or at extreme angles. 5-axis laser cutting is utilized for fabricators, metal spinners, and hydro formers.

Work With Us

Superior Joining Technologies, Inc. (SJTI) provides multi-axis precision laser cutting, drilling, and welding to meet the tight tolerances required by the aerospace and other industries. We utilize the Trumpf 5000W TruLaser Cell 7040 for our 3D laser cutting services.

With a working range of 13 feet x 5 feet Y x 30 inch Z and maximum simultaneous axis speeds of 98 inches per second, it is the most advanced system of its kind in the Midwest. With the ability to construct a cutting and welding program from a CAD model, the prep time is greatly reduced, and the use of its integrated rotary axis makes the processing of tubular components highly efficient. To download a datasheet on our 5-axis laser cutting and welding capabilities, please click here.

Trumpf TruLaser Cell 7040 5000W 5-Axis 3D Laser

Trumpf TruLaser Cell 7040 5000W 5-Axis 3D Laser

Machine Specifications

Working Range

Workable Clamping Area

Maximum Material Thickness as a General Rule for Cutting

|

Maximum Axes Speeds

Maximum Accelerations

Accuracy4Maximum Repeatability

Maximum Positioning Accuracy

Control and Laser

|

3 Reduced accuracy/dynamics with fully extended Z = 750 mm axis for cutting 2D parts. It is recommended to use the 2D cutting box to cut 2D parts.

3 Reduced accuracy/dynamics with fully extended Z = 750 mm axis for cutting 2D parts. It is recommended to use the 2D cutting box to cut 2D parts.

4 Pure mechanical accuracy without software compensation, according to VDI 3441 across the entire working range. The accuracy achievable in the workplace depends, amongst other things, on the part geometry, its pre-treatment, material, and its position in the work area.