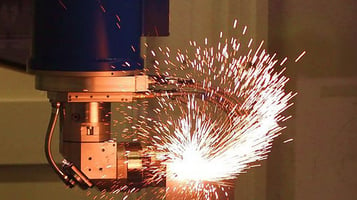

Precision Laser Cutting Services

From the products we use daily, to the infrastructure around us, quality is of the utmost importance. For manufacturers, one nonconforming part can negatively impact final product performance, safety, and reliability.

Ensure parts for your application surpass fit, form, and function requirements with high-value precision laser cutting services from Superior Joining Technologies, Inc. (SJTI). We are an Illinois-based certified laser cutting company that specializes in turnkey laser-cutting for critical applications. From prototypes to small batches or full-scale production runs, we can help you get exactly what you need.

The STJI Edge

As a certified laser cutting company, SJTI provides multi-axis precision laser cutting services to meet the stringent tolerances of high-performance applications across a range of industries, including aerospace, military, and medical instrumentation. Our specialty is three-dimensional parts that require cutting on difficultly curved surfaces or complex parts.

We operate the Trumpf 5000W TruLaser Cell 7040, which is the most advanced system of its kind in the Midwest. It has a 13-foot by 5-foot Y-axis and a 30-inch Z-axis working range coupled with a maximum simultaneous axis speed of 98 inches-per-second.

By combining cutting-edge equipment and highly skilled operators, SJTI provides industry-leading precision laser cutting services.

- Shorter lead times

- Greater precision

- Minimal to zero finishing requirements

- Heightened efficiency

- Reduced downtime

Since we produce pinpoint cuts, there are few or no finishing requirements. Edges are smooth and free from burrs. The beams are also tightly focused, resulting in no internal flaws from heat exposure. Because our laser system can produce precise cuts, quality checks take less time. With our lasers, cuts in sheet metal can be made very close to one another. This maximizes the number of parts created, which lowers production time, material waste, and overall project costs.

Laser Cutting Explained

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The term "laser" originated as an acronym for "light amplification by stimulated emission of radiation". Laser cutting systems create patterns and designs by cutting into materials. The process utilizes a focused laser beam to melt, burn, or vaporize material in a localized area. A co-axial gas jet is used to eject the molten material and create a kerf. A continuous cut is produced by moving the laser beam or workpiece under CNC control.

This fabrication method is capable of producing intricate parts without custom-designed tooling. It’s ideal for use on a variety of materials. However, at SJTI we focus our laser on cutting metals.

Pinpoint laser beam sizing and innovative computer-aided controls make laser cutting highly accurate. Additional benefits include:

- High-quality cut

- No finishing

- Low heat input

- Non-contact

- Small heat-affected zone

- No surface blemishing

- Low distortion

- Flexible

While laser cutting is an effective way to engrave and cut materials, like all trades, it has a unique set of challenges. Inexperienced or untrained technicians can have trouble with thicker materials or produce defects such as uneven cuts, blowout, and thermal runaway. When partnering with SJTI, these issues are of no concern. A team of knowledgeable and highly trained personnel sets SJTI apart in the laser-cutting marketplace. They have a customer-first, quality-driven mindset and are backed by a dedicated inspection crew.

Industries Served

We can create just about any shape or form with laser cutting. Our lasers can make thousands of cuts in metal forms per hour, with every cut from the first to the last having the same micrometer level of precision. SJTI's laser-cutting services are perfect for the following industries:

- Aviation

- Aerospace

- Space-relate projects

- Medical

- Nuclear

- Industrial

- Maritime

- Defense

Your Laser-cutting Service Provider

When it comes to fabricating a high-level assembly, a manufacturer may have dozens, if not hundreds, of parts that require significant workforce hours to make. Integrating a new process like laser cutting into a production line can cause headaches, which can ultimately slow finished product delivery. Permit your workforce to focus on their primary functions by partnering with SJTI for laser cutting. Typically, outsourcing this process costs noticeably less than manufacturing in-house. These savings are realized by reducing:

- Labor costs

- Overhead maintenance costs

- Distractions

- Redundancy costs

Our laser-cutting services create a cost-effective cutting solution, whether you need a single part, batch of prototypes, or production order.

As a certified laser cutting company, your laser-cutting needs are covered.