Tungsten Inert Gas (TIG) Welding Services

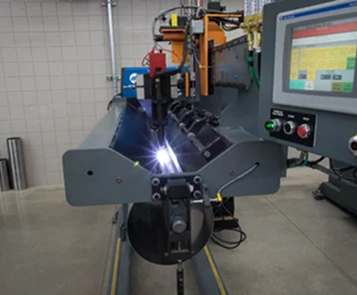

When joining of critical components, or for situations requiring pinpoint fabrication, there’s no better process than Gas Tungsten Arc Welding, (GTAW). It can be performed on a range of materials, and, when done correctly, produces welds with the utmost quality and purity. Optimize your application with trustworthy Tungsten Inert Gas (TIG) welding services from Superior Joining Technologies, Inc. As a Nadcap GTAW welding company, we offer services to clients across a range of industries and specialize in precision TIG welding for critical applications.

Gas Tungsten Arc Welding Services

TIG Welding Explained

Tungsten Inert Gas Welding services, which is sometimes called TIG welding services, is a type of arc welding that produces the weld using a non-consumable tungsten electrode. Inert gases such as argon or helium are used to protect the welded area from contamination. A column of plasma, made up of highly ionized gas and metal vapors, conducts energy across the arc and is produced by a constant-current welding power supply.

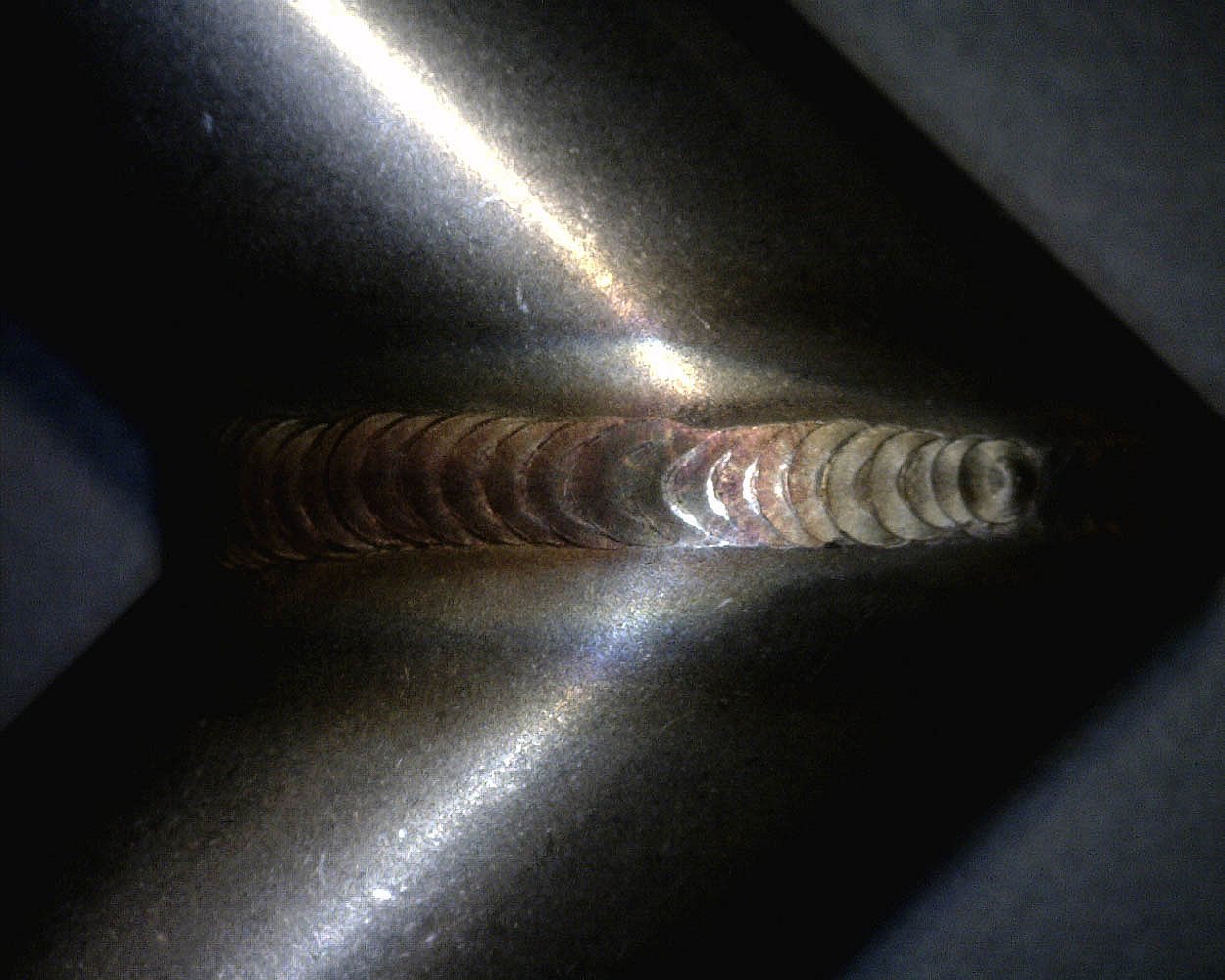

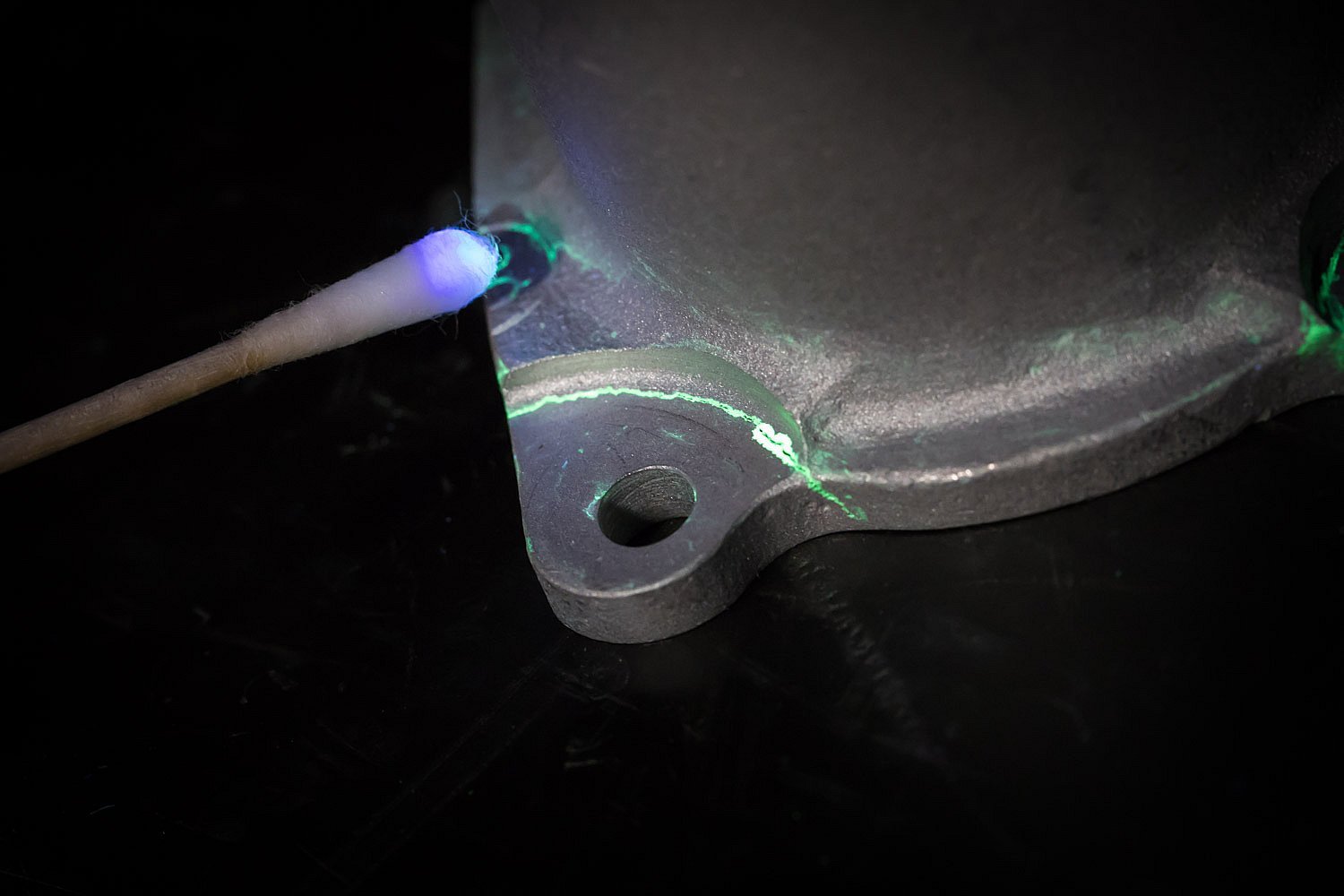

Unlike more straightforward welding methods that produce slag, or chips of metal that tend to flake off of welds, TIG welding services are much cleaner. It’s a perfect process when welding slag is prohibited, such as for applications demanding a neat and attractive appearance.

Characteristics of GTAW include:

- Produces high-quality, superior welds

- Compact, thin weld seam

- Easily applied to thin materials

- Welds made with or without filler metal

- Enables precise control of welding variables

- Yields low distortion

- Clean process

Before GTAW, welding aluminum was difficult. Since large quantities of aluminum were used during World War II, finding a solution became critical. Today, the GTAW process is still prized all over the world.

The SJTI Advantage

Traditional GTAW is considered the process of choice to produce high-quality welds. It has a series of challenges, such as weld energy limitation influenced by the weld pool dynamics and typically slow manual wire feed rates, that can become an obstacle for the inexperienced or untrained, however. That’s where SJTI takes the lead.

We have a team of experienced and highly skilled welders dedicated to performing precision TIG welding on critical applications. Their unrivaled craftsmanship, flexibility, and dedication to quality enable SJTI to take on jobs few others can do. Our GTAW capabilities include:

- GTAW

- NADCAP manual GTAW

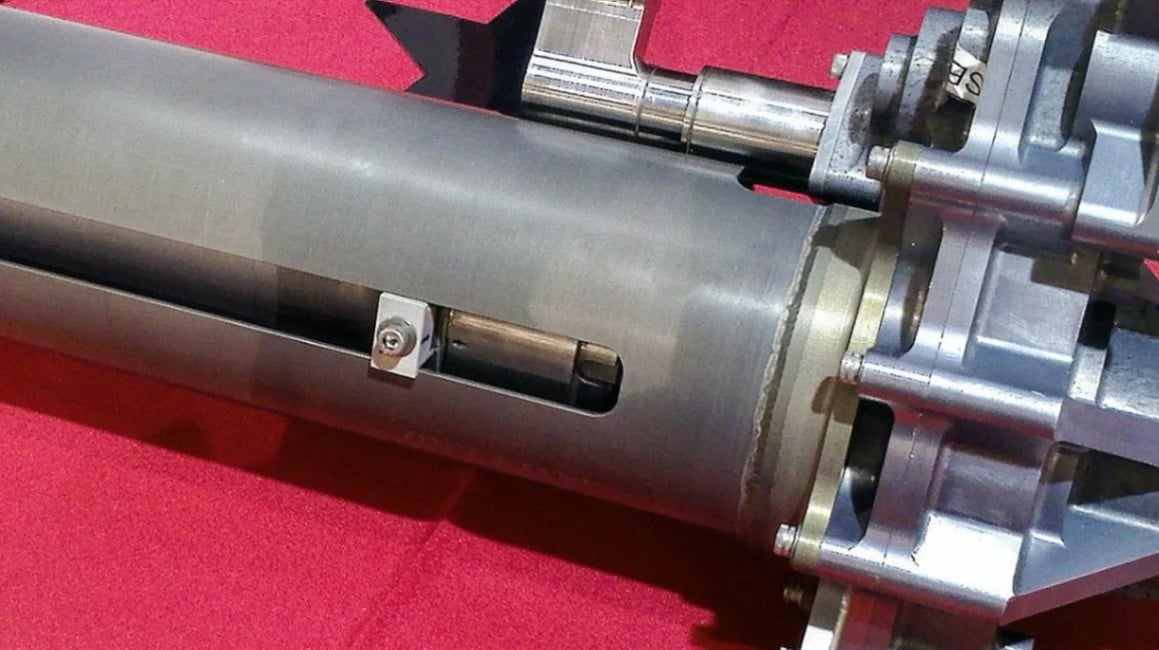

- Micro GTAW

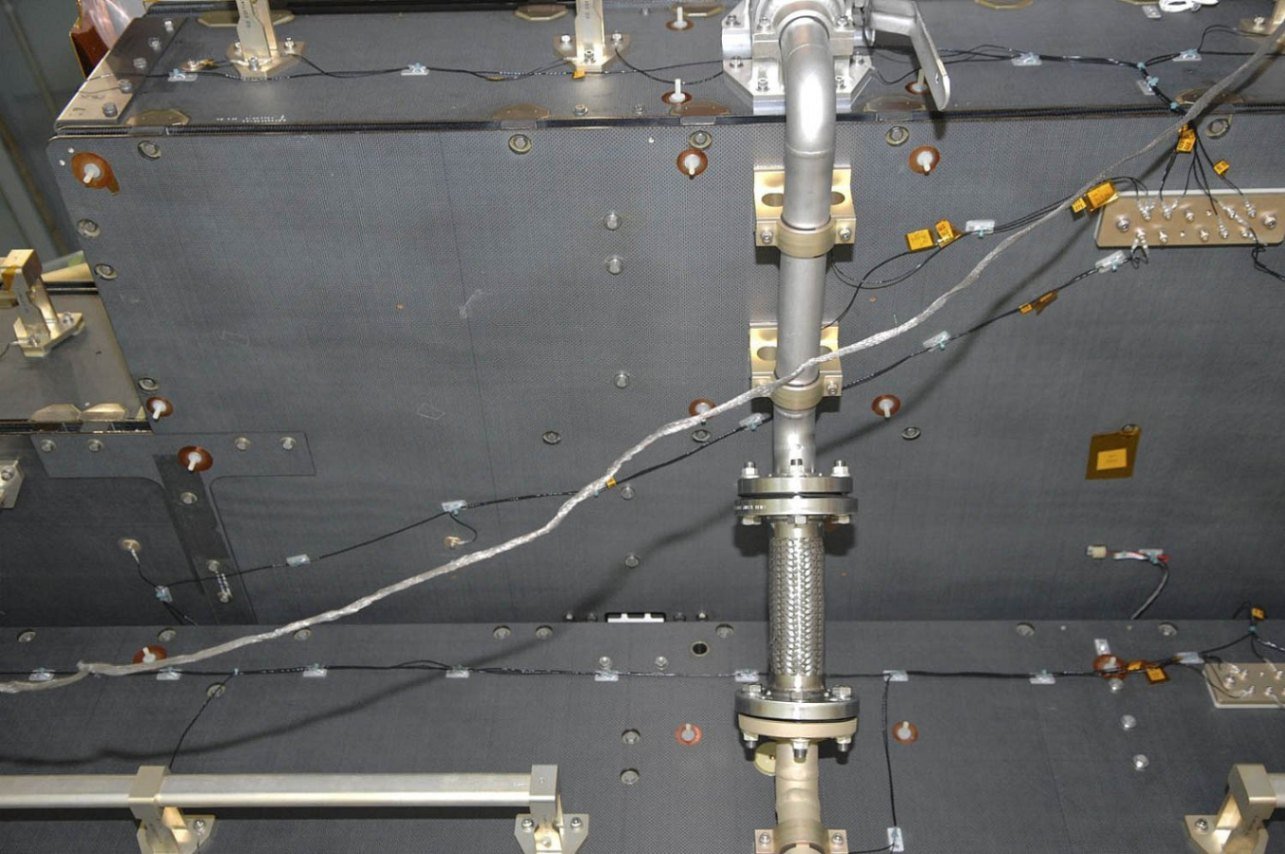

- Longitudinal seam GTAW

Industries Served

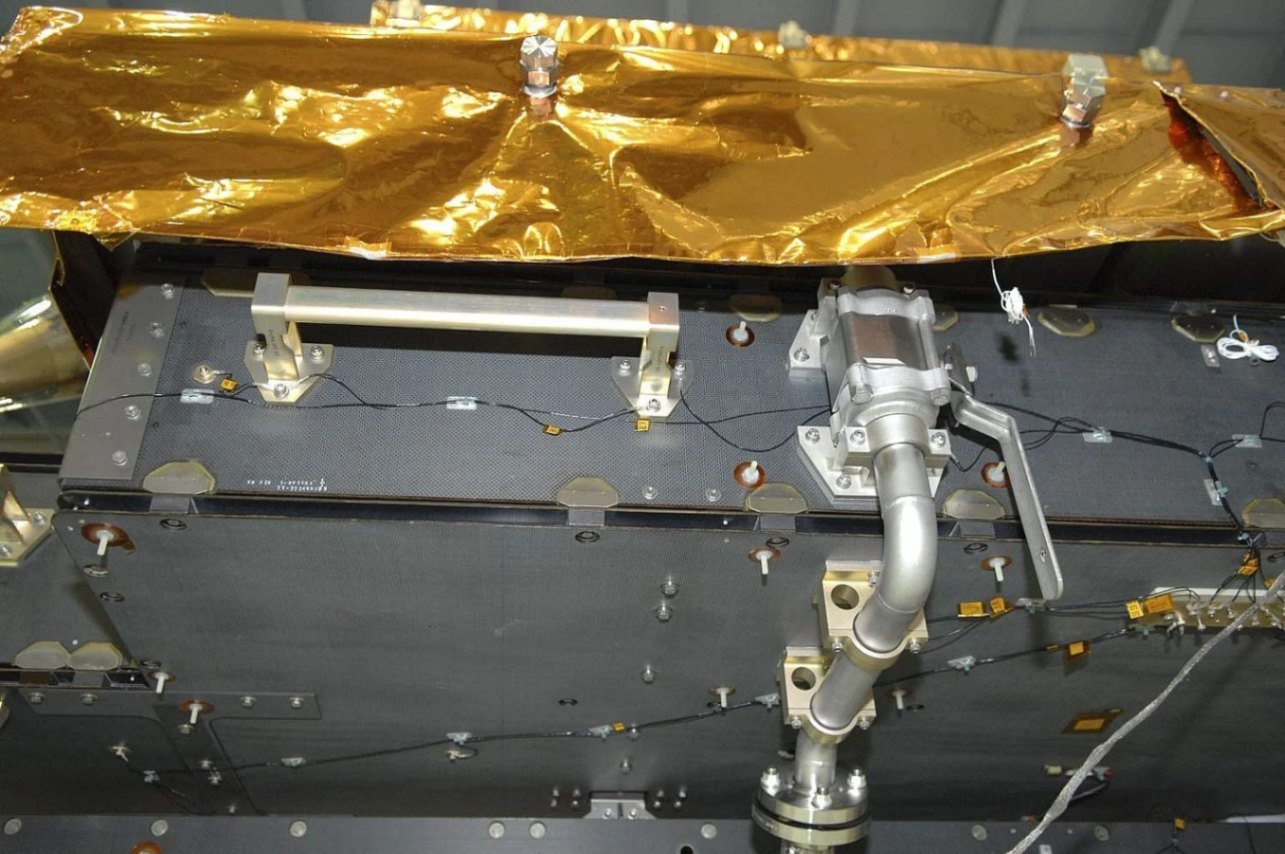

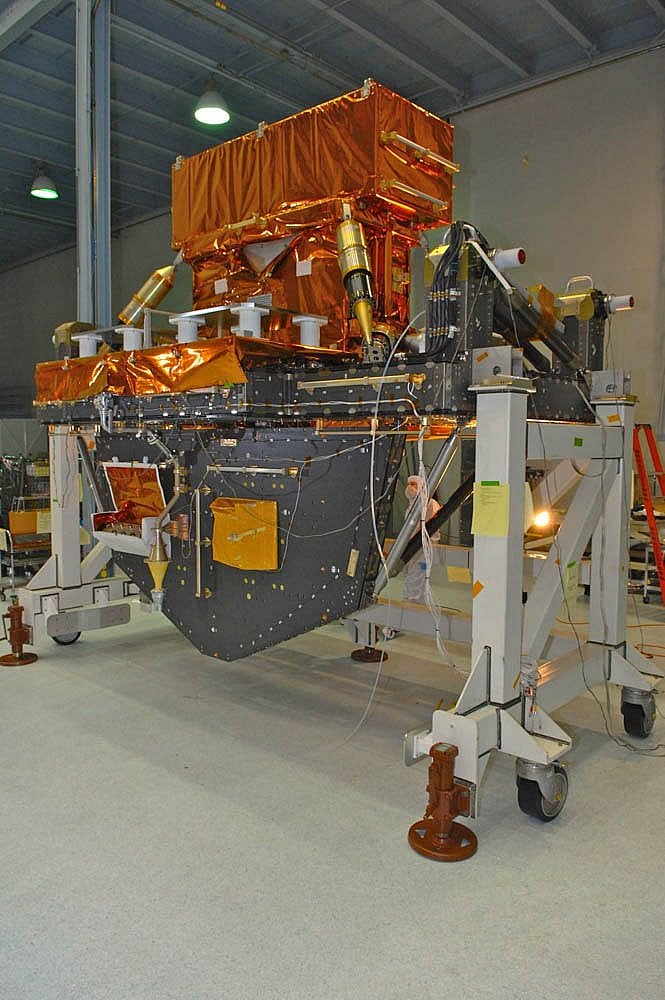

Manual TIG welding services require a level of operator skill and judgment that comes only with experience, and SJTI is proud to have a team of craftsmen capable of providing this service. The quality and precision of manual GTAW can benefit applications across a range of industries. Examples include:

Materials

One of our core competencies is NADCAP-accredited GTAW Fusion Welding services, which produce clean and highly controllable precise welds that are perfect for thin-walled, high-performance materials. We perform manual Tungsten Inert Gas welding services on a variety of materials.

- Aluminum

- Carbon Steel

- Stainless Steel

- Titanium

- Inconel

Heat-Sensitive Application Solutions

Micro TIG welding services are the process of executing minute welding operations on intricate assemblies with minimal heat. Performed with a microscope and custom small GTAW torch, this welding method takes the joining of critical parts to a new level.

Whether you need to connect complex parts or repair existing assemblies with minimal weld buildup, you can trust SJTI to deliver the highest quality results. The benefits of micro Tungsten Inert Gas welding services include reducing heat input, minimal warpage, and smaller weld sizes.

Your GTAW Service Provider

We work closely with you to understand project requirements and deliver a superior end product on time and within budget. The micro TIG welding services work exceptionally well in very small or intricate precision components in the medical industry, repairs, and aircraft industry, where parts are manufactured from thin materials. SJTI, is a Nadcap accredited Tungsten Inert Gas (TIG) welding services provider. When you have critical welding needs, our precision TIG welding services fit the bill. Contact us for additional information.

Request a QuoteArticles Related to TIG Welding Services

How a Contract Welding Partner Adds Process Engineering Expertise | Superior Joining Technologies, Inc.

How a Contract Welding Partner Adds Process Engineering Expertise | Superior Joining Technologies, Inc.

Closing the Gap | Superior Joining Technologies, Inc.

Closing the Gap | Superior Joining Technologies, Inc.

What NDT Techniques are Best for Surface and Subsurface Weld Verification? | Superior Joining Technologies

What NDT Techniques are Best for Surface and Subsurface Weld Verification? | Superior Joining Technologies