Laser Beam Welding Services

What Is Laser Beam Welding?

Laser beam welding uses a precisely focused beam of light to fuse metals together. In laser beam welding, the laser focus spot is targeted on the workpiece surface to be welded. The concentration of light energy converts into thermal energy which causes the surface of the material to melt. This heats the surface by the process of surface conductivity.

How Does Laser Beam Welding Work?

Laser Beam Welding (LBW) employs a precisely focused beam of light to fuse metals together. A wide variety of materials including copper, steel, stainless steel, brass, silver, gold and platinum can be joined by the energy produced by the laser process. Among the most notable advantages of laser beam welding are the low input of heat and the ability to join intricate and even microscopic assemblies.

Laser beam welding can achieve three different types of welds.

- Conduction mode welding - Lower energy level forming a wide and shallow weld nugget

- Conduction/penetration mode - Medium energy density results in more penetration

- Penetration or keyhole mode - Deep, narrow welds

Laser beam welding achieves immense improvements in productivity and quality compared to conventional welding processes. This process can weld thin materials faster than GTAW with significantly less heat input. Thin plate and sheet metal products can be produced very quickly with greatly reduced distortion which reduces or eliminates down-stream production costs.

Laser output is not electrical and does not require a flow of electrical current. This eliminates any effect of magnetism and does not limit the process to electrically conductive materials. Laser beam welding does not require a vacuum and does not produce x-rays.

Is Laser Beam Welding Right For Your Project?

Laser beam welding is ideal for joining components made of materials with a high melting point and high heat conductivity. Laser beam welding is a great solution for hard-to-access areas and for extremely small components.

Advantages of Laser Beam Welding

- A no-contact process

- Useful for materials that are difficult to weld using other methods

- Useful for hard to access areas

- Useful for extremely small components

- Low input of heat

- Helps to enable the reduction of material thickness

- The laser beam size is tailored to match the material thickness

- Ability to join intricate and even microscopic assemblies

- Works with high alloy metals without difficulty

- Transmitted over long distances with minimal loss of power

- Narrow heat affected zone

- Low total thermal input

- Welds dissimilar metals

- No filler metals are necessary

- No secondary finishing is necessary

- Extremely accurate

- Reduction of distortion

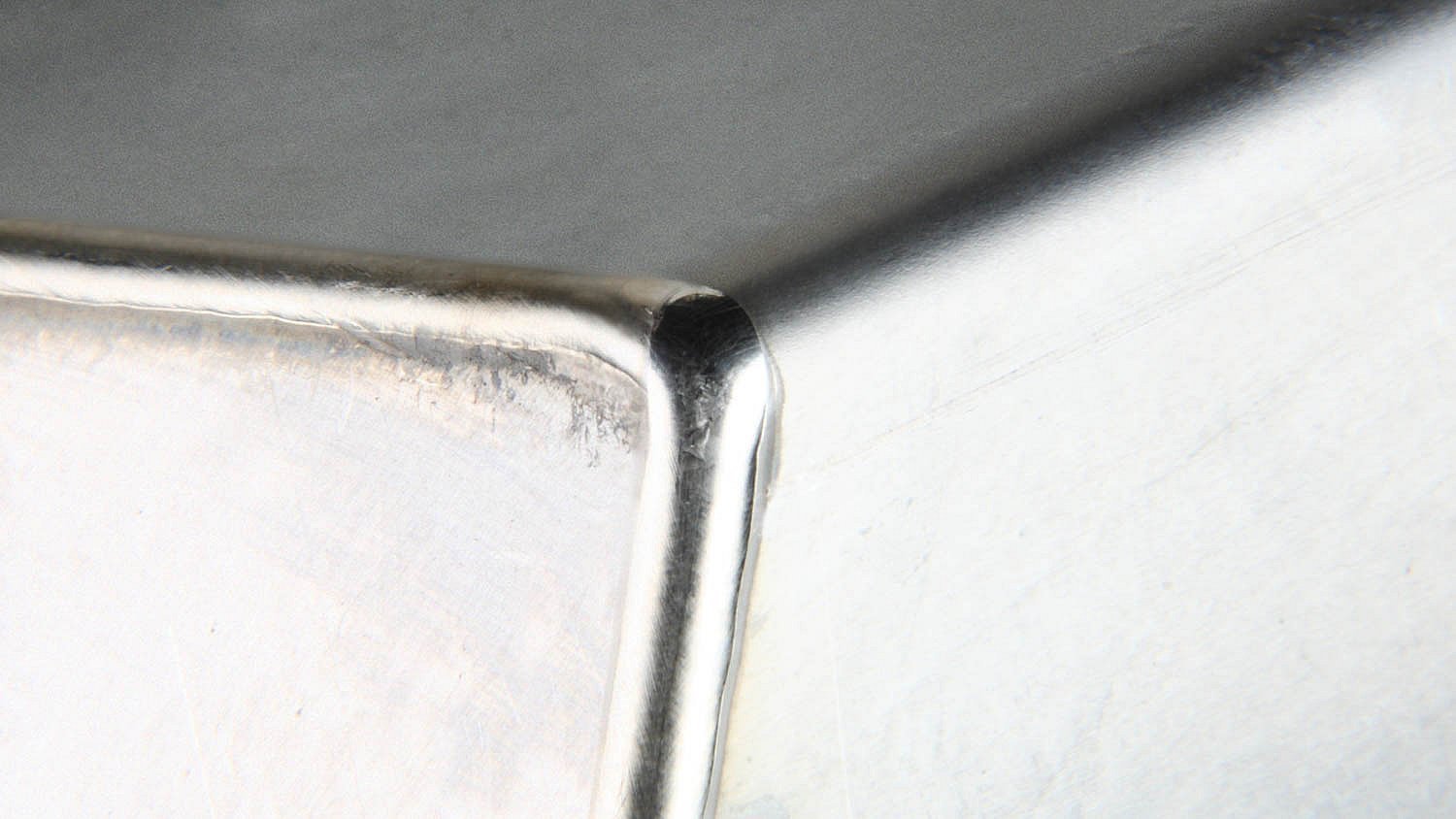

- Produces deep and narrow welds

- Low distortion in welds

- High-quality welds

- Repeatable defect-free process

Laser Beam Welding Services Offered

Micro Laser Beam Welding: Projects a nanometer-diameter beam to fuse different metals together.

Laser Beam Welding with Powder Deposition: Laser beam is directed through a processing head with focusing optics. The processing head delivers a powdered metal alloy substance in a conical shape in the beam path. The powder liquefies and creates a small pool of molten bases.

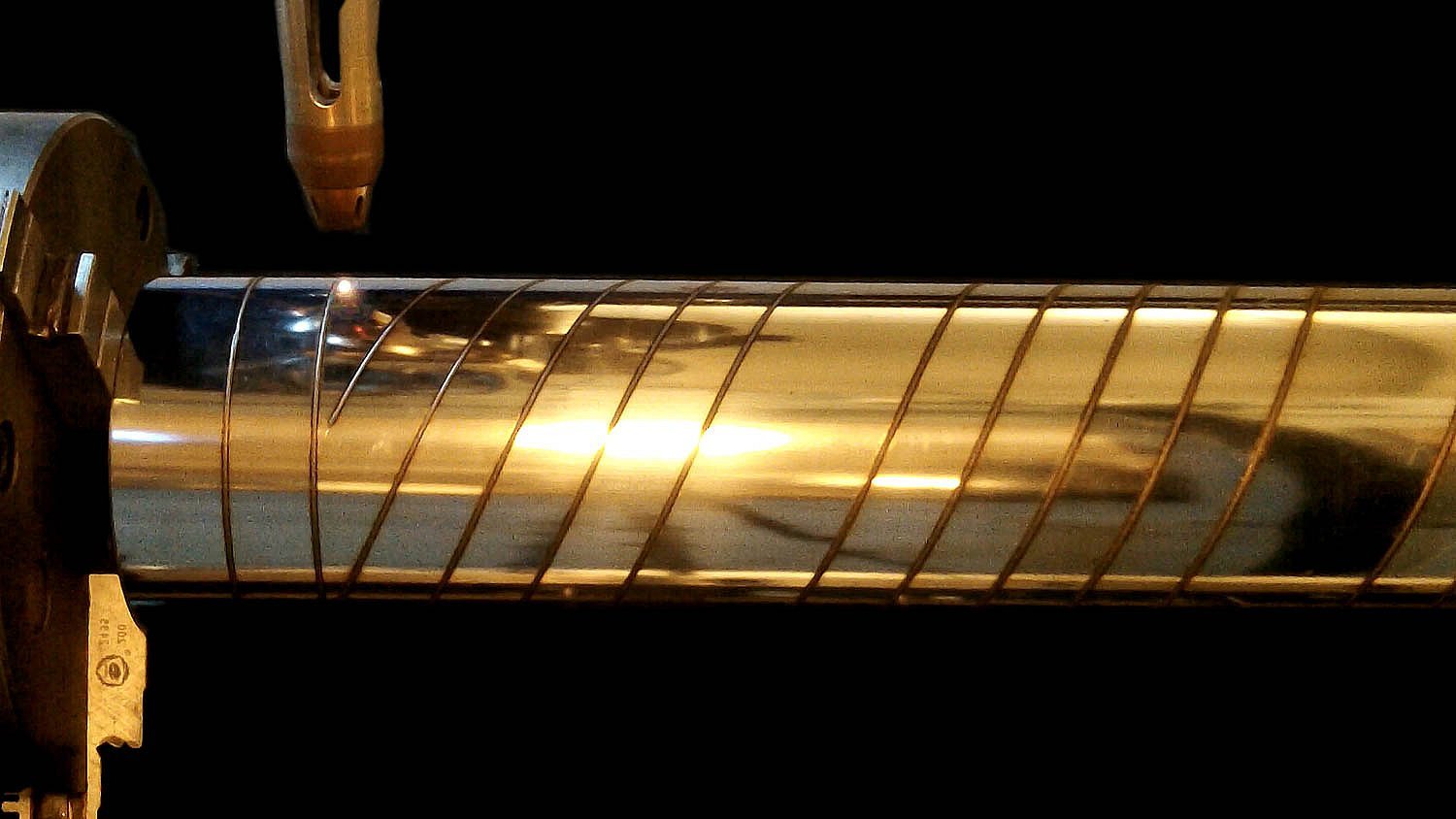

Multi-Axis Laser Beam Welding: Used when tight tolerances are required or when working with three-dimensional parts that require welding on difficultly curved surfaces.

Applications

Nadcap accredited laser beam welding is commonly used in the following applications but is certainly not limited to:

- Fuel rails

- Heat exchangers

- Metal tubing

- Metal boxes

- Medical devices

- Compressor parts

Materials We Work With

Superior Joining Technologies, Inc. offers laser beam welding for the following materials.

- Copper

- Steel

- Stainless steel

- Brass

- Silver

- Gold

- Platinum

- Carbon steel

- Aluminum

- Titanium

- Low alloy steel

- Nickel

- Molybdenum

- Kovar

Why Choose Superior Joining Technologies, Inc.?

At Superior Joining, our years of experience and technical expertise are combined for a professionally finished product time after time. We work with a large variety of industries that need laser beam welding services including aerospace, medical, defense, industrial, nuclear, maritime, and more.erosSuperior Joining Technologies, Inc. is a Woman-Owned Small Business that is ITAR Registered, an FAA Repair Station, (FFL) Federal Firearms Licensed Facility, Accredited by Nadcap, AS9100 and ISO9001.

The highly experienced staff of Superior Joining Technologies, Inc. (SJTI) offers high-quality laser beam welding services and continually leverages their expertise in precision welding to deliver the best possible solution to each customer's unique design specifications. Super Joining Technologies is Nadcap accredited for laser beam welding.