We are excited to announce the recent addition of an Advanced-Technology Dimensional Measuring System to our metrology department. The integration of three different sensors in one system enables us to provide definitive verification of our products.

We are excited to announce the recent addition of an Advanced-Technology Dimensional Measuring System to our metrology department. The integration of three different sensors in one system enables us to provide definitive verification of our products.

Video Measurement/Optical Comparator

The optical sensor provides two complementary methods of measure. Video measurement is primarily used as an optical camparator for non-contact measurement applications.

The 10:1 zoom optics mode provides the highest-level resolution optical/video performance. It is specifically designed to measure smaller parts, with fine detail geometry with fully automated program capability for rapid throughput of larger part quantities.

Touch Trigger Probe

Single-point touch trigger probing adds versatility to our measurement capability. Using a touch trigger probe, we can measure intricate 2- or 3-dimensional features that are difficult to image, or surface boundaries that are inaccessible to video.

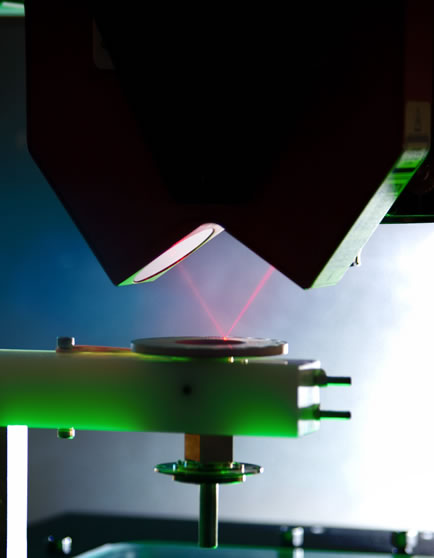

DRS Laser

The DRS (Digital Range Sensor) Laser Probe provides non-contact, high-resolution 3-dimensional surface contouring to supplement video measurements.

As one of the sensors in this multi-sensor measurement system, the metrology software integrates the DRS Laser data points as easily as those gathered by video measurement. Both linear and area sans are easily programmed into automatic measurement routines for accurate measurement of surface contours.

| Smartscope Specifications | |

| XYZ Stage Travel: |

300 x 150 x 200 mm |

| Area Accuracy: | (1.8 + 4L/1000) µm |

| Z Accuracy: | up to: 1.4 + 6L/1000) µm |